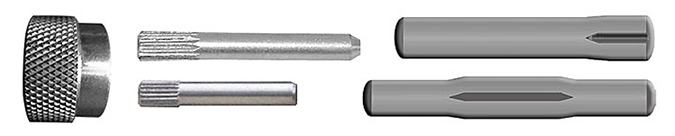

Knurled & Grooved Pins

Standard Horse Nail makes a wide range of knurled and grooved pins to meet your machine requirements. Our experienced team will also work with you to determine the correct pin for your specific application in size, fit and material.

Knurled Pins

The knurled serrations are roll formed into the pin. Unlike grooved pins, knurled pins are categorized as either straight, helical or diamond describing the pattern that appears on the pin.

The serrations on a knurled pin, when compressed by insertion into a hole, result in forces which hold the fastener in place. Radial forces are more evenly distributed around the diameter of a hole for knurled pins than for grooved pins. This is because a knurled pin has more points of contact with a hole than a grooved pin.

Grooved Pins

Grooved Pins have unground straight cylindrical sides with three or more swaged or extruded grooves equally spaced around the diameter to displace material beyond the diameter of the pin. The ends of grooved pins are usually crowned or chamfered and are available in a variety of types for various design considerations.

How Grooved Pins Work

When grooved pins are installed, the material displaced by the grooves is forced back into the grooves and reacts against the sides of the hole to promote retention of the pin or stud.

Standard Horse Nail offers a wide range of knurled and grooved pins in size, material and types to match your specifications and exceed your requirements. Our team is more than happy to help you select the correct pin for your application.

For more information about our knurled pins and grooved pins, call us today at 724.846.4660 or click here to contact us.